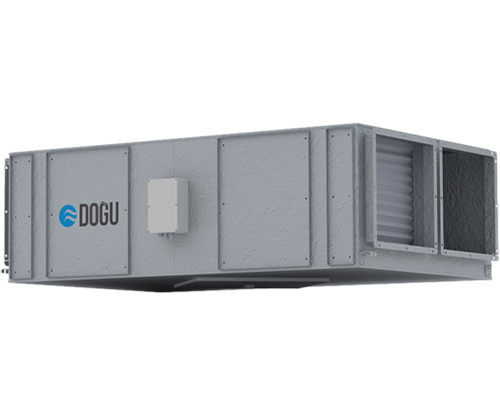

ACA Rectangular Variable Air Volume Device (VAV)

- Home

- Flow Control Units

- ACA Rectangular Variable Air Volume Device (VAV)

ACA Rectangular Variable Air Volume Device (VAV) is designed for controlling airflow in rectangular ducts in projects requiring comfort and hygiene, such as operating rooms, clean rooms, and special processes.

Description

Material and Usage Features:

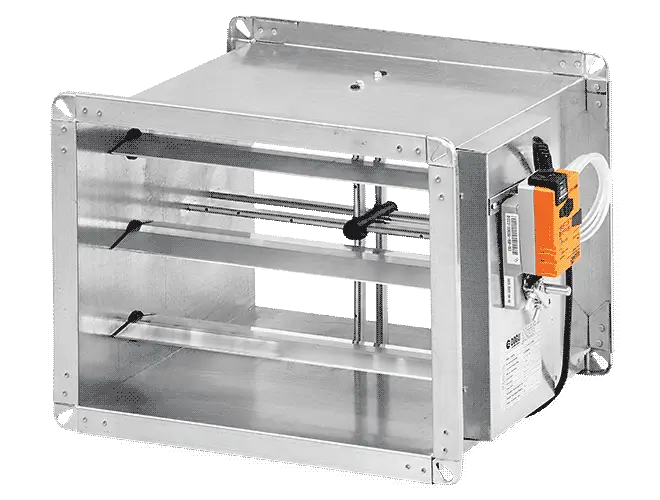

ACA Rectangular Variable Air Volume Device’s (VAV) casing is standardly made from galvanized steel sheet, with an AISI 304 stainless steel option available. The blades and differential pressure tubes are made from aluminum profiles. The damper motor is fixed onto the casing. Variable air volume (VAV) systems can save up to 50% energy in fan motor consumption and are used in ventilation applications for controlling variable airflow systems and duct pressure. The device operates at flow rates between 216 – 17,000 m³/h. All VAV devices are calibrated in the VAV laboratory according to the specified flow rates and are tested for air tightness according to DIN EN 1751. With seven measurement stations simulating actual field conditions, calibration is completed. Casing air tightness is Class B according to DIN EN 1751, and the device meets DIN EN 1946/4 and VDI 6022 hygiene standards.

Features:

- Efficient performance with low pressure loss due to oppositely working blades.

- Available in galvanized or stainless steel.

- Air tightness tested according to DIN EN 1751.