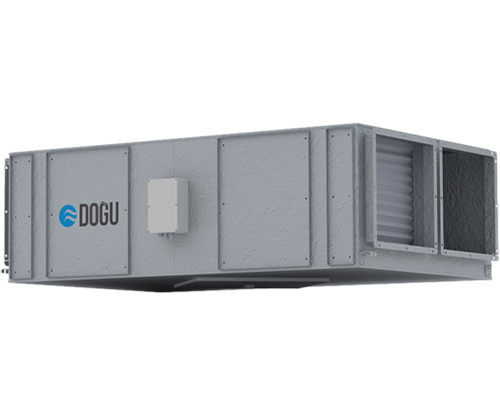

RTER Rotary Energy Recovery Unit

- Home

- Heat/Energy Recovery Units

- RTER Rotary Energy Recovery Unit

RTER Rotary Energy Recovery Unit is designed to meet the fresh air needs of areas such as restaurants, shops, historical buildings, and offices. This unit operates on the principle of reducing the energy required for air conditioning while fresh air is being conditioned.

Description

Energy Recovery Process

The RTER works in integration with indoor climate control systems by transferring the heat from the exhausted air to the incoming fresh air through the energy recovery rotor. Thanks to the automatic control system, the unit operates 24/7, adapting to the need without requiring intervention.

Efficiency and Ease of Use

Rotary Energy Recovery Units operate quietly and efficiently with EC motor-driven plug fans. The unit’s airflow can be adjusted in 3 stages using the room panel that comes standard with the product, providing a customized performance experience based on user needs.

Features:

- Eurovent Certification

- Low-noise, high-efficiency EC plug fans

- Plug & play control system

- Optional water or electric heater coils

- Optional duct-type silencer for quieter environments

- Optional smart automation solutions

- High external static pressure

- Optional temperature, CO2, and pressure sensors

- Bypass damper (free cooling and recuperator freeze protection)

- High-efficiency rotary heat recovery (up to 77% efficiency)

- 3-speed control

- Compliant with ErP 2018 regulations

- Double-walled panel structure with 50 mm insulation.