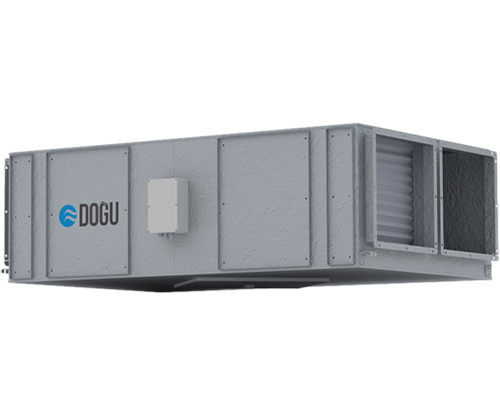

DOGU HVAC has once again demonstrated its expertise in delivering tailored solutions for projects requiring precise climate conditions in the food industry. At Kervan Gida’s Dryff Dried Food Factory in Izmir Tire, DOGU HVAC designed and manufactured a custom Desiccant Rotor DKS Series Air Handling Unit with a capacity of 7,500 m³/h, configured with mixed air and a DX coil, entirely in line with the facility’s operational requirements.

The specially integrated desiccant rotor technology ensures precise humidity control in the production area, maintaining targeted low humidity levels consistently over extended periods. Manufactured from silica gel, the rotor features specially engineered channels on the drum surface, enabling high-efficiency adsorption and maximising the dehumidification process. Excess moisture in the ambient air is effectively captured, ensuring stable climate conditions throughout the production cycle. One of the key advantages of the rotor is its ability to retain high moisture removal capacity even after many years of operation.

The air handling unit, constructed with Eurovent-certified panel technology, stands out with its high thermal insulation, double-skin design minimising thermal bridging, and robust casing. These features not only enhance the unit’s energy efficiency but also ensure long-term, trouble-free operation. This durability reduces operational costs and lowers maintenance frequency.

Through this prestigious project, DOGU HVAC has delivered a bespoke solution fully meeting the stringent requirements of food production environments. Implementing desiccant rotor dehumidification technology in the food industry demands high technical expertise, which DOGU HVAC successfully demonstrated through its project-specific engineering approach. As a result, the production areas of Kervan Gida’s Dryff Dried Food Factory benefit from a perfect balance of comfort, energy efficiency, and compliance with quality standards.